After sludge buildup in Saskatoon’s wastewater treatment plant brought operations to a standstill in 2010, the city was left looking for answers.

After three years, the city finally unveiled their solution: an environmentally friendly nutrient facility.

The new plant is the first of its kind in Canada.

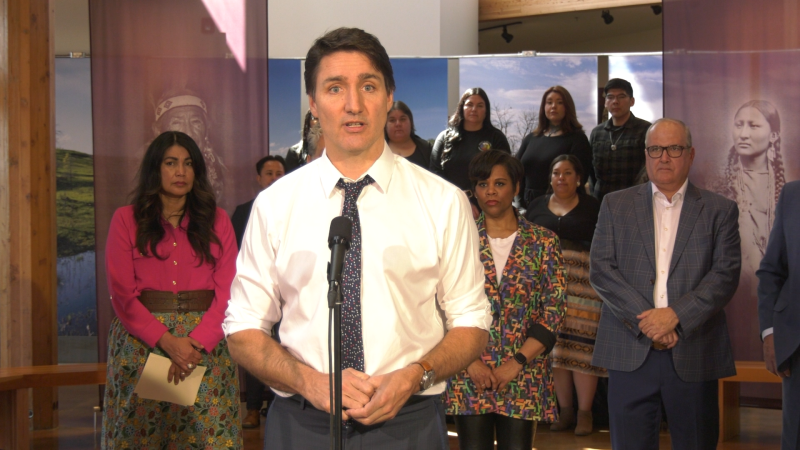

“We’re the first ones to take this step. Other cities can wait and say we’ll check to see how it’s going to be, or follow behind us shortly. But we’re the first ones to get there,” said Mayor Don Atchison.

The new facility will reduce sludge buildup by removing phosphorous and nitrogen from wastewater streams and turning them into fertilizer.

“That means we are not going to have the fear of the plant being shut down. It means envorinmetanly, for the people that are downstream from us, to not have to worry about the sewage being released in an emergency type scenario,” Atchison said.

The fertilizer, known as “crystal green”, is made through the pear process. Elements of the wastewater are converted into tiny fertilizer pears that are harvested, washed, dried and bagged before they’re distributed.

Most of the fertilizer will be used for golf courses, lawns, and landscaping.

Unlike traditional fertilizer, the pearl system uses a slow-release technology.

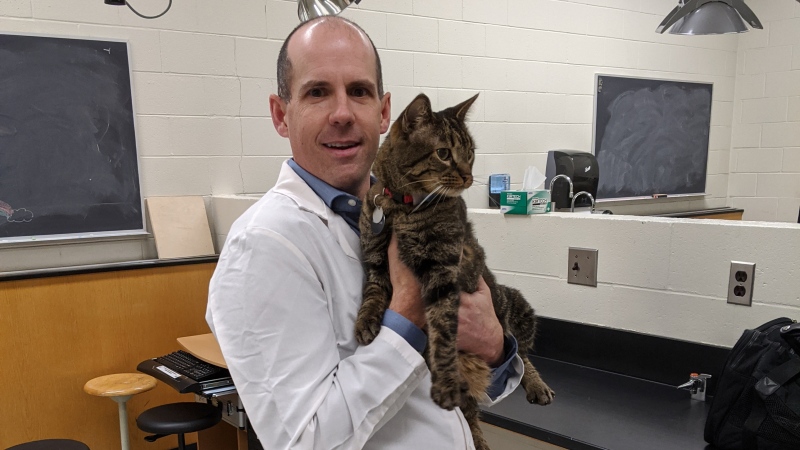

“It releases slowly over many months, and that’s what’s good for the plants because they get the nutrients when they need them,” said Philip Abrary, president and CEO of Ostara, the company behind the new facility.

The process is supposed to be good for the environment because it’s a sustainable, closed-loop method. Using the wastewater as a source of phosphorous means less demand on phosphorous mining. The slow release technology also means that more of the nutrients are used effectively and less end up making their way into nearby waterways.

The nutrient recovery facility cost the city about $4.7 million to purchase and install, but it’s a cost that won’t be coming out of the tax payers’ pockets.

Sales from the crystal green fertilizer are expected to make up the cost within the next five years, and after that, further profits will be used to cover the facility’s operating costs.